Irrigation Kits

11 Categories

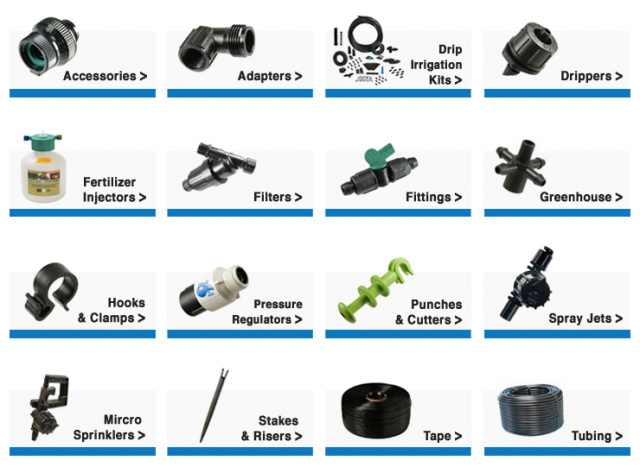

Irrigation Supplies

29 Categories

Fertilizing

3 Categories

Gardening

29 Categories

Landscape Lighting

3 Categories

Electric Fencing

28 Products

Outdoor Drainage

5 Categories

Outdoor Misting

2 Categories

Patio & Equipment Covers

5 Products

Poultry Supplies

5 Categories

PVC

3 Categories

Beekeeping Supplies

32 Products

Holiday Inflatables

12 Products

Merch & Swag

3 Products

Clearance

5 Products

As drip irrigation systems become more user-friendly, more individuals are successfully designing and installing systems themselves and saving the expense of hiring irrigation professionals to accomplish these tasks. Most systems, in fact, can be installed quickly with no tools necessary other than a standard household pair of scissors. Weve compiled some tips from installation professionals provided especially for those weekend warriors to help with the DIY installation process of a standard drip irrigation system.

| Hot Water for Tubing: A trick among drip irrigation professionals is to briefly insert the end of a piece of tubing into a cup of hot water before attempting to connect fittings to the tubing. As a side note, lubricants should never be used on drip irrigation tubing. |

| Place Tubing in the Sun:Many drip irrigation installation experts place their roll of tubing in the sun prior to installation, which allows the tubing to warm up and become more flexible. |

| Punching Holes in Tubing: A little known but valuable tip is to punch holes in your poly tubing when it is cold, like in the morning before the sun warms the tubing too much. Punching holes in tubing when it is warm can be a challenge and frustrating. |

| Know your Soil Type: Most drip irrigation installation experts agree that before installing any drip irrigation system a person should identify what type of soil they have. Soil type greatly influences how water penetrates and travels to your plants' roots. There are 3 soil types: Clay, Loam and Sand. Clay soils are tightly packed and water does not penetrate quickly into the soil. Drip emitters with slower drip rates, like .5 gallons per hour (gph), are ideal for this soil type to prevent water from accumulating on the surface. Sandy soil experiences the quickest water penetration rate, so a drip emitter with a faster flow rate, like 2 gph, would be recommended. Loamy soil falls in between these two in regards to water penetration rate, so a drip rate of 1 gph would work well. |

| Cutting Tubing: Don't be fooled into buying a special tool to cut poly tubing, which can easily be cut using household scissors. |

| Don't Over Tighten: Many drip irrigation installation professionals note that a common mistake made by first time drip irrigation installers is to over tighten pressure regulators, backflow preventers and other faucet assembly parts. Over tightening these products can actually damage the products and cause them to leak. All parts in a drip irrigation system should only be hand tightened, and teflon tape or glues should not be used. Keep in mind that two different thread types are commonly used with drip irrigation systems. Hose threads are sometimes referred to as MHT for male hose threads and FHT for female hose threads. Pipe threads also can be designated as MPT or FPT. Hose threads and pipe threads are not compatible, but adapters are available to make connections between the two when necessary. |

| Control Your Water: A great way to manage the water flow in your drip system is by using shut off valves for the specific size of tubing you are installing. Drip irrigation professionals use shut off valves in two ways. First, the valve can be installed inline which allows water flow to be adjusted based on your watering needs. Secondly, the 1/4" valves can be used as a drip emitter. This allows the amount of water to an individual plant to be adjusted or shut of completely depending on your watering needs. |

| Fixing Holes in your System: Holes in tubing happen. Fortunately, a tubing coupler can repair holes in poly tubing without having to replace the whole system. Experts simply cut out the damaged part of the poly tubing and then reconnect the two fresh ends with the coupler. Click here to see how to use our Perma-loc fittings. |

| Reuse your Fittings: Some reusable tubing fitting brands (like Perma Loc) have become popular among drip irrigation professionals. These fittings are unique in that they can be reused an unlimited number of times as opposed to compression or barbed fittings which can only be used once. Drip systems can change from year to year and reusable fittings allow you the flexibility to do so easily and economically. |

| Insert Goof Plugs Easily; A well kept secret among drip irrigation installation professionals is how to install goof plugs easily. Anyone that has tried to insert a small goof plug into micro tubing will appreciate this tip. Try using a pair of needle nose pliers to grip the opposite end of the goof plug that you wish to insert into the micro tubing. The added leverage of the pliers will make this task a breeze. Click here to see our how to video. |

| Install a Timer: Drip Irrigation experts recognize that in order to reap the maximum benefits from a drip irrigation system a timer is a must. Timers allow water schedules to be set and carried out without worry day after day. Although drip systems are efficient without a timer, an addition of a timer will save you more time and more money. |

| Clean Your Filter: Drip irrigation professionals note that regularly cleaning the filter in a drip system can help keep your system running at full efficiency. A filter is an important component of any drip system, and keeps debris out of your system that could clog the small openings on most drip emitters. |

| Winterizing your Irrigation System: Winterizing a drip irrigation system is easy. Timers and head assembly components (backflow preventers, filters, pressure regulators) need to be removed and stored indoors. Most drip irrigation parts are made of extremely durable plastic which can withstand freezing temperatures as long as the water is removed from the system. Drip irrigation experts commonly install a threaded end cap at a low point in the system which allows the water to be drained out of the system easily. Once the water is drained out, they simply screw the cap back on and it's ready for the winter. Click here to see our how to video on Winterization. |